|

The compact telehandler

The compact Weidemann telehandlers are unique in the combination of lift height, width and machine capacity. With the all-wheel drive and all-wheel steering, you are absolutely stable and well-equipped for many different tasks. Those who drive a Weidemann telehandler simply will no longer give it up.

|

|

The Weidemann benefits at a glance

All-wheel steering, low centre of gravity and excellent stability All-wheel steering, low centre of gravity and excellent stability

Thanks to the all-wheel steering and the undivided chassis, Weidemann telehandlers are particularly manoeuvrable and very stable. The low centre of gravity of the machine supports the stability even more.

|

High quality powder coating High quality powder coating

Quality creates added value. The powder coating is a key feature of the Weidemann quality standard. In contrast to the conventional wet painting, it greatly increases the service life and is more efficient and also environmentally friendly in the process.

|

|

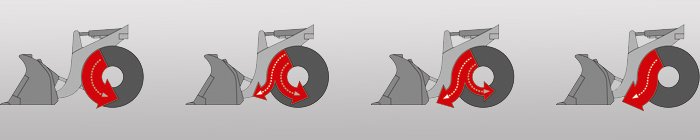

Driver assist system vls (Vertical Lift System) Driver assist system vls (Vertical Lift System)

The vls (Vertical Lift System) makes a fluid working principle possible and, through a partially-automated telescoping movement, supports the work in a complex operating environment. The machine’s stability is improved with the approximate vertical lifting and lowering movements. The vls has proven itself well in the area of agriculture and our innovation received several international awards.

|

|

Sturdy telescopic arm and enormous lift height Sturdy telescopic arm and enormous lift height

The telescopic arm is designed to be sturdy and stable and is placed in the centre of the machine, which causes little distortion. The parallel motion takes place hydraulically. The sliding components in the inner pipe of the telescopic arm are maintenance free. All important hydraulic lines are well protected against external influences. With our compact Weidemann telehandlers, you reach amazing lift heights with the best stability and compact dimensions.

|

|

High shear forces from planetary axle High shear forces from planetary axle

The drive via the planetary axle increases the torque on the wheel and thereby improves the shear force. Due to the optimal ratio between the shear force and machine capacity, you work flexibly and economically at the same time.

|

|

100% differential lock 100% differential lock

If necessary, the up to 100% connectable differential lock offers you maximum traction and shear force and keeps the tyre wear low (switched off during normal operation).

|

|

Large selection of tyres Large selection of tyres

The optimal tyres for every subgrade - you have a wide selection of different tyres available for your Weidemann. You can find which tyres are right for is right for your machine...

|

|

Large selection of attachment tools Large selection of attachment tools

Use your machine as a multi-tool - you have a wide selection of attachments available for your Weidemann. Here you can find which attachment in what size is right for your machine...

|

|

Power take off and three-point rear tool holder Power take off and three-point rear tool holder

Optionally, the Weidemann telehandlers can be outfitted in the rear with a power take off and three-point rear tool holder. In combination with corresponding rear hydraulics, these options make it possible to operate rear attachments. This makes your machine even more flexible in use.

|

|

Compact design, compact dimensions

Compact dimensions in the 2 x 2 metre class Compact dimensions in the 2 x 2 metre class

Telehandlers from Weidemann are built extremely compactly. The width and height of all machines is less than 2 metres. That is why our telehandlers are also ideal for use in confined spaces and are therefore unique in their combination of lift height, width and machine capacity.

|

|

Small inside radius Small inside radius

All telehandlers in our series, from the T4108 to the T6025, have particularly small inside radii. The manoeuvrability achieved in this way makes the machines into all-rounders on every application site.

|

|

Optimal service accessibility

Easy-to-open engine hood Easy-to-open engine hood

The engine hood with gas compression springs can be opened upward with just one handle for regular service and maintenance work. The hydraulic oil tank, air cleaner, engine oil fill opening, oil dipstick and cooling water are therefore quickly and easily accessible - real added comfort.

|

|

A workplace that motivates

Comfortable cabin and good circumferential visibility Comfortable cabin and good circumferential visibility

The spacious cabin meets the current European machinery directive (2006/42/EC) according to ROPS and FOPS protection and offers plenty of headroom and elbow room. The complete glazing provides the operator with an excellent circumferential visibility the entyre working area.

|

|

Ergonomic cockpit Ergonomic cockpit

More spaciousness in a cab that was designed and developed according to the latest findings in safety technology and ergonomics. Plenty of legroom, clearly arranged instrument clusters, a comfortable driver's seat and an optimal view of the attachment. A workplace that motivates and fully supports the operator.

|

|

Good view to the right Good view to the right

The view to the right is often not sufficient in many telehandlers. At Weidemann, this is ensured through the large pane on the right, the low positioning of the telescopic arm and the steeply sloping engine hood. This always gives you a perfect view of the area to the right next to the machine and of the right-hand mirror.

|

|

Good view of the freight Good view of the freight

A telehandler's advantages come into play when it comes to stacking the freight high. The view upward is also crucial in order to securely place the load at a great height. With Weidemann telehandlers, the cabin and pane are designed so that the operator always has the freight in view, even at maximum lift height.

|

|

Ergonomic joystick - everything in one hand Ergonomic joystick - everything in one hand

Perfect control of the machine and functions via a joystick of the latest generation. The innovative joystick with ergonomically arranged, illuminated touch controls creates user friendliness and multi-functionality.

|

|

Easy entry Easy entry

With one step, you can get into the machine's cabin comfortably. This is made possible by the low design and the associated low entry height.

|

|

Adjustable steering column Adjustable steering column

The steering column can be individually adjusted according to the operator's request. This ensures that every operator can work with the machine ergonomically and fatigue-free.

|

|

Brake-inch pedal

The hydrostatic all-wheel drive is combined with the brake pedal for Weidemann machines. By "inching," this makes it possible to crawl until the travelling operation comes to a standstill. With the partially depressed brake-inch pedal , you can drive slowly in crawl speed at full engine speed precisely to the millimetre and at the same time lift quickly. If the pedal is pressed further, the machine is braked. The advantage of the brake-inch pedal lies in the optimal power-output distribution of the engine rated power. In addition, it is not possible to stall the machine.

|